Video: How Automatic Cow Milking Machine Works | How To Machines 2024, July

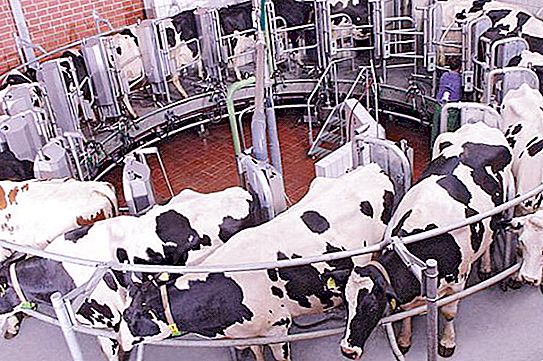

In the field of agriculture, many specialists work. Milking machine operator is an important profession in which a person collects milk automatically. Workers are needed on various farms. Specialists collect and record milk, and are also responsible for the conditions of its storage and the implementation of rules for caring for animals.

Duties

The milking machine operator must properly operate and maintain the milking installations. He needs to know about animal diseases, standards of maintenance and treatment. It is important to pay attention to the livestock needs for vitamins needed to produce a high quality product.

The duties of the machine milking operator include the following tasks:

- Disinfection of premises.

- Compliance with the rules of feeding and watering livestock.

- Selection of animal feed.

- Preparation for milking and cattle care.

- Processing and storage of milk.

- Accounting for products and the implementation of measures to improve work efficiency.

An important requirement is the ability to timely recognize diseases of the udder, which can affect the general condition of the animals. Prevention of protection against ailments is also carried out by the machine milking operator. People with disorders of the musculoskeletal system, diseases of the heart, blood vessels and joints are not accepted for this work.

Knowledge

The operator should be aware of:

- The device and the rules for the use of devices.

- The rules of assembly, disassembly, care of devices.

- Milking technique.

- Rules and regulations for feeding, watering livestock.

- Animal needs for vitamins.

- Methods of increasing milk productivity.

- The technique of cooling milk.

- First Aid Rules for Livestock.

- Medicines and disinfectants.

All this knowledge is necessary for the operator to work successfully and obtain high-quality milk.

How the milking machine works

The principle of operation of the device is based on the physiological characteristics of animals. During machine milking of cows, activation of nerve receptors located on the nipples occurs. Tactile stimulation is considered a precondition for the transmission of an impulse to the brain, due to which the release of the hormone oxytomycin occurs. Then he goes into the tissue of the udder.

There is a contraction of muscle fibers surrounded by alveoli, so milk is sent to the cisterns and the ducts of the milk. The whole process lasts 30-60 seconds. An effective stimulation of the nipples of cows is considered to be a calf. Therefore, the technique imitates its sucking movements.

How is the apparatus prepared

For the operator to work, it is important to learn how to prepare the device. The procedure is lubrication. To increase milk yield, suckers must be treated with special oil or cream. This procedure stimulates blood flow inside the udder.

The design takes into account the needs of livestock. The flow of milk controls the process. All cows need an individual approach, as the procedure differs depending on the breed, size and other nuances.

Cow Training

It should be noted that machine milking is not suitable for all animals. The reason is the non-compliance of livestock with the requirements set by device manufacturers. Milking is performed only under the following conditions:

- The udder should be tubular, round or bowl-shaped. And its bottom is even.

- The distance from the udder to the ground cannot be less than 45 cm.

- The length of the nipples is 6-9 cm, and the diameter in the middle part is from 2 cm. The distance between the front nipples is 6-20 cm, and between the front and rear 6-14 cm.

- The duration of the issue between quarters should not be more than 1 minute.

- The duration of milking should not be more than 7 minutes.

- The volume of milk after dosing should not be more than 200 mg.

The most popular devices are Tandem devices. Devices are suitable for those farms where there is no time-selected milk flow rate of the herd and milking. Maximum productivity is achieved using the installation of the company "Herringbone", but for its use, cows must be selected for productivity and milk flow rate.

Milking procedure

The duration of the process is on average 5 minutes. It should be borne in mind that during the entire period it is necessary to carefully monitor the behavior of the animal, as well as the flow of milk through the device. If the fluid flow is reduced, then the back of the udder is machine-fed.

The mechanical finishing procedure lasts no more than 30 seconds. Do not overdo milking devices on the nipples, as this can lead to pain, inhibition of milk flow, and injuries to the nipples. Before using the device, it is necessary to study its characteristics in order to prevent errors in operation. Any inaccuracy can lead to negative results, so it is important to follow the instructions.

Training

To get a job as a milking machine operator, you must complete training for 1400 hours on a full-time basis. Then the specialist is provided with a document on the study of the program and the assignment of a profession (3rd category).

During the training period, it is mastered:

- Basics of livestock.

- Veterinary sanitation and hygiene.

- Safety regulations.

- Ecology protection.

- Production activities.

During training, checks are performed. To get a document, you need to pass an exam, practice and interview. Training is carried out in colleges, technical schools and combines. Often, contests of machine milking operators are held to select the best specialists and award them.

Housing

Necessarily provided housing operator milking machine. The object is located in a private area (near the farm). But housing can be provided far from the place of work, if there is a special leadership program for this. When renting a room, the employee is fully or partially compensated for the payment. During training, future specialists are provided with accommodation in special buildings or dormitories.

In some cases, housing is not issued. If the machine milking operator lives far from the livestock farm, he is provided with free travel from home and a return delivery. These subtleties are negotiated with the management and indicated in the contract. In some localities, delivery and housing are not provided. Then the employees need to pay these costs on their own.

The salary

Vacancies of machine milking operators are in demand, but the salaries of specialists are low. The average income is 15 thousand rubles. The highest salaries are for specialists in the Novgorod and Murmansk regions and the Kamchatka Territory (about 22–25 thousand rubles). Low salaries are observed in the Kaluga and Arkhangelsk regions. The level of income depends on working conditions, specialist workload and the amount of work.

Thus, operators are important workers in livestock farms.