Video: classification of rolling stocks in c&w 2024, July

The work of the railway is very similar to an enterprise, for its normal functioning a lot of employees from different professional areas are involved. Mostly graduates of the railway technical school become employees in this field. But sometimes, specialists who have received advanced training with ordinary professional education are also hired. It all depends on the complexity and responsibility of the post.

general information

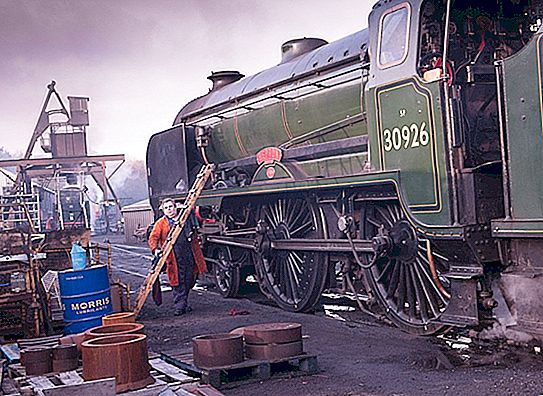

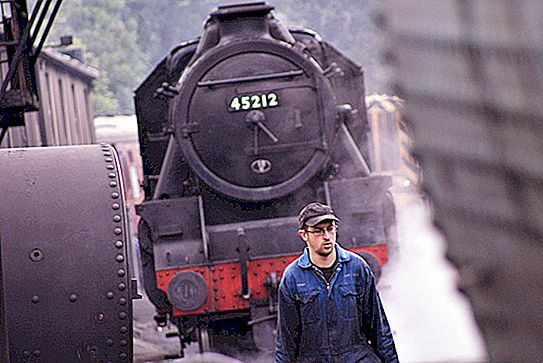

For transporting goods and passengers, various vehicles are used, including locomotives, trains, trolleybuses and others. All this requires repair and maintenance for normal and serviceability. And the fitter of the rolling stock is engaged in this, he determines the serviceability and quality of parts and the entire mechanism, identifies defects and inaccuracies in the assembly of equipment and eliminates them. The duties of this employee include locksmithing, replacing the railway equipment, as well as adjusting and testing the assembled units after repairs.

Requirements

This employee is a worker and can get a position only after completing a full secondary and vocational education. Also, employers admit applicants who have received professional training in the workplace without additional education, in addition to secondary education, to the service. This position is divided into categories. In order to receive the next level, the rolling stock repair fitter must undergo advanced training and work at the relevant enterprise for at least one year.

Employers pay attention to workers with good physical fitness. They must be hardy, have good hearing, vision, memory. The linear and voluminous eye, the ability to control the hands is important. To fulfill duties, a person must have developed visual and technical acumen, good resistance to stress. It’s not enough to finish a railway technical school and possess all these skills, you also need to be approached for health reasons. Persons with diseases of the musculoskeletal system, respiratory tract, cardiovascular and nervous systems are not allowed to work. Also, allergy sufferers, people with hearing impairment, vision or mental disorders cannot count on a post.

Knowledge and responsibilities for first grade

Before starting his work, an employee who has the first rank should learn the basics of plumbing, understand the names, brands, purpose and methods of using tools, materials, simple devices and instrumentation. It should also be versed in liquids that are used to lubricate and flush parts of railway vehicles.

His responsibilities include running threads on minor parts such as nuts and bolts. He can be instructed to clean parts from nicks, burrs and other defects that occur during welding. He is engaged in cutting, cutting and filing parts. Also, his duties include the maintenance of simple locksmiths and their sharpening.

Knowledge and responsibilities for the second category

The employee holding this position is required to study the principle of maintenance and repair of rolling stock. In addition, he must understand the purpose and rules of operation of the most common types of special and universal tools and instrumentation. His knowledge includes the basic techniques for performing locksmith work during the repair and assembly of simple assemblies that are connected using bolts and rollers. He must understand the mechanical properties of the materials that get to him for processing. Examine tolerances, fit, qualifications, roughness. He also needs to know how to properly couple and unhitch wagons and tugs.

Rolling stock repair fitter performs machining, fabricates and repairs parts according to 12-14 standards. He creates simple parts and high-quality materials, assembles and disassembles parts and simple assemblies that are attached to each other by means of rollers and bolts. He may be instructed to drill holes using mechanized and hand tools. The duties of the employee may include threading with dies and taps in a complete set of rail mounts. In addition, his competence may include the scene and release of wagons, tugboats, etc.

Knowledge and responsibilities for the third category

During the training period, the repairman of the rolling stock of the third category should find out how they are arranged, what they are intended for and how the main components related to objects requiring repair work interact. To know how special and universal devices and instrumentation are arranged. Understand the basic properties of the materials with which he will work. What are the types of connection of nodes and parts, roughness, tolerances, fit, quality. In addition, his knowledge should include the technical information necessary for adjusting the tests of the mechanisms entrusted to him.

The instruction to the mechanic of the rolling stock suggests that he carries out repair work and is engaged in the manufacture of parts according to 11-12 qualifications. He must disassemble the auxiliary parts of the objects that are entrusted to him for repair work, provided that the parts of the composition have a tight and sliding fit. He is engaged in the installation and disassembly of some devices of pneumatic systems. The employee connects the nodes and cotter pins, while observing the dimensions, locations and conditions of the movable landings. He may be assigned to test the performance of pneumatic systems that operate under pressure. His responsibilities also include the regulation and testing of some mechanisms of railway equipment.

Knowledge and responsibilities for the fourth category

In order to fulfill the assigned duties in a high-quality manner, the fourth-level rolling stock fitter must possess certain knowledge, namely, to learn the main parts of the objects entrusted to him for repairs. Including their design, what they are intended for, how they interact and how to assemble and disassemble them correctly. How are they arranged, what are they intended for and how to operate instrumentation properly. To learn the design of special and universal equipment, to know the technical conditions of assembly, testing and adjustment of units and components of the composition.

His responsibilities include repair work and the manufacture of parts according to 7-10 qualifications. The fitter of the rolling stock must disassemble and assemble the main components having different types of landings. The employee determines how high-quality and workable parts are, and also determines what kind of repair they need. To carry out the connection of groups and nodes with all varieties of planting, in addition to tight and tension. He regulates and tests the assembled nodes, as well as compiles documentation, namely defective statements.

Knowledge and responsibilities for the fifth category

Before starting work, the employee must study the design features, operational characteristics and the interaction of the nodes that were transferred to him for repair work. Learn all the technical conditions for the repair, know how to assemble the main components, how to control and regulate the assembly and operation of the components. His responsibilities may include disassembling, repairing, and installing equipment. Moreover, nodes with a tight and tight fit are trusted in him. He also must perform locksmith work in conditions of 6-7 qualifications. The employee checks whether the parts and assemblies were assembled correctly, performs the scrapping of parts that have large fitting areas, regulates and tests mechanisms and assemblies after assembly.

Knowledge and responsibilities for the sixth category

The fitter of the rolling stock should know what there are ways of marking and installing nodes, checking installation work, accuracy of the quality of repair work. Also, his knowledge should include methods that allow you to check and identify damaged parts.

He should be familiar with the methodology for restoring the functionality of rolling stock. The duties of this employee include testing, checking for accuracy and putting into operation devices and equipment received for repair. He must identify and prevent defects in all assembly groups of the composition.

Knowledge and responsibilities for the seventh category

The employee is obliged to learn the design features of installations, components and other equipment of all series, which are received for repair work. Know what rules and adjustment technologies exist using stands, centering and running. Methods of diagnosis, testing, permissible load on the equipment, as well as preventive measures aimed at preventing wear and breakdowns.

His responsibilities include maintenance and repair of railway transport, including diagnostic work, adjustment, adjustment, running-in parts. He must carry out repairs and debug electronic equipment, ensure the safe use of compounds.